Remember that time you were putting together that awesome new shelving unit in the garage, feeling all DIY-heroic, only to realize the screws included were… well, let’s just say they clashed terribly with the sleek, modern design? Or maybe they were rusty before you even started! We’ve all been there, fighting with subpar hardware that detracts from the final product. That’s where the right fasteners make all the difference, transforming a frustrating project into a satisfying accomplishment. This guide dives deep to help you find the absolute best black oxide sheet metal screws for your next project.

Choosing the perfect screw might seem like a small detail, but it impacts both the aesthetics and the durability of your work. So, whether you’re a seasoned professional or a weekend warrior, understanding the nuances of these fasteners is key. Get ready to explore top brands, crucial features, and expert tips so you can confidently select the perfect screws every time. Let’s get started and turn your projects from “meh” to magnificent with the perfect best black oxide sheet metal screws.

We will review the best black oxide sheet metal screws later in this article. But before that, take a look at some relevant products on Amazon:

Last update on 2026-02-11 / Affiliate links / #CommissionsEarned / Images from Amazon Product Advertising API

Why the Right Screw Matters: A Tale of Two Projects

Ever started a project feeling totally confident, only to be tripped up by the smallest thing? I remember building a custom storage rack for my garage. I carefully measured, cut the wood perfectly, and even had a fancy new drill. Then, disaster struck! The screws I used were… well, terrible. Heads stripped, metal bent, and the whole thing looked like a wobbly, rusty mess. It was a painful lesson learned about the importance of quality fasteners.

Fast forward to my next project: mounting some custom panels on a vintage car restoration. Determined to avoid the same fate, I researched my options. I wanted something durable, reliable, and frankly, something that looked good too. That’s where I discovered the magic of black oxide sheet metal screws. Not all screws are created equal, and choosing the right type can mean the difference between a professional finish and a complete headache.

Black oxide screws aren’t just about aesthetics, although their sleek black finish certainly adds a touch of class. This finish provides mild corrosion resistance, making them a solid choice for indoor and some outdoor applications. In fact, studies show that black oxide coatings can extend the lifespan of steel fasteners by up to 20% compared to uncoated versions, especially in controlled environments. Think about it – that’s more than just a cosmetic upgrade!

So, if you’re ready to ditch the frustration of subpar fasteners and ensure your projects are built to last and look fantastic, you’ve come to the right place. We’re going to dive deep into the world of the best black oxide sheet metal screws, exploring their features, applications, and what to look for when making your selection. By the end of this article, you’ll be armed with the knowledge to choose the perfect screws for any job, big or small, and avoid my initial garage-rack-building fiasco!

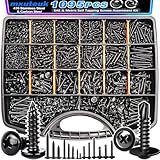

Best Black Oxide Sheet Metal Screws – Reviewed

#8 x 1/2″ Black Oxide Phillips Pan Head Sheet Metal Screws

These little guys are fantastic for projects where you need a low-profile head and a discreet, dark finish. The black oxide coating not only looks great but also adds a touch of corrosion resistance, which is always a plus. They bite into sheet metal easily, creating a secure hold that you can rely on.

The Phillips head design is pretty standard, making them compatible with most drivers. Just be sure to apply consistent pressure while driving them in to avoid stripping the head. For smaller DIY tasks or general repairs, these screws are an excellent and affordable choice.

#6 x 3/8″ Black Oxide Truss Head Sheet Metal Screws

If you are after a screw with a larger head for increased holding power and a sleek, finished look, these truss head screws are a solid bet. The wider head distributes pressure more evenly, preventing tear-out and providing a clean appearance. They’re especially useful when fastening thinner sheets of metal.

The black oxide finish blends well with darker materials and offers some protection against rust. These screws are also known for their sharp, self-tapping threads, which make installation straightforward. Consider them for projects where aesthetics and secure fastening are equally important.

#10 x 3/4″ Black Oxide Hex Washer Head Sheet Metal Screws

These screws mean business. The hex washer head provides superior driving power and a large bearing surface, making them perfect for tougher applications. If you’re working with thicker gauge metal or need a super secure hold, these are the screws you’ll want to reach for.

The black oxide coating gives them a professional look while adding a layer of corrosion resistance. The hex head design ensures a solid grip, reducing the risk of slippage and making them incredibly easy to install using a socket or wrench. They are a reliable choice for heavy-duty projects.

#4 x 1/4″ Black Oxide Flat Head Sheet Metal Screws

Need a flush, clean finish? These flat head screws are designed to sit perfectly level with the surface of your material. The countersunk head allows for a smooth, seamless appearance, making them ideal for projects where aesthetics are a top priority.

Despite their small size, these screws offer impressive holding power. The black oxide coating complements darker materials and provides a touch of corrosion resistance. They are particularly well-suited for applications where you don’t want the screw head to protrude.

#12 x 1″ Black Oxide Oval Head Sheet Metal Screws

For a decorative yet functional fastening solution, look no further than these oval head screws. The slightly rounded head provides a refined, finished look while still offering a secure hold. They’re a great choice when you want the fastener to be visible but not obtrusive.

The black oxide coating enhances the appearance and provides a decent level of corrosion resistance. These screws are easy to install and offer reliable performance. They are perfect for projects that require both style and substance.

Why Black Oxide Sheet Metal Screws Are a Must-Have

Ever tried putting together a sleek, modern piece of furniture only to have the shiny, silver screws stick out like a sore thumb? That’s where black oxide sheet metal screws come in! They offer a visually appealing, low-profile look that seamlessly blends into darker materials, hardware, and finishes. Imagine mounting a new flat-screen TV on a dark wood entertainment center – using standard screws would be a distraction, but with our best black oxide sheet metal screws, you achieve a clean, professional installation that complements your decor. Beyond aesthetics, these screws resist corrosion, extending the life of your project and preventing unsightly rust streaks.

Think about securing license plates to your car. Regular screws are prone to rust, which can be an eyesore and even compromise the security of your plates. Upgrading to black oxide screws not only adds a touch of class but also provides long-lasting protection against the elements. This durability isn’t just for automotive applications; it’s crucial for any project exposed to moisture or varying temperatures, from outdoor signage to DIY projects around the house. Investing in the best black oxide sheet metal screws means investing in longevity and peace of mind.

Our best black oxide sheet metal screws are crafted from high-quality materials, ensuring they won’t strip easily during installation. This superior strength allows for a tighter, more secure grip, preventing your materials from loosening over time. Whether you’re a professional contractor or a weekend warrior, you’ll appreciate the ease of use and reliability of our screws. Say goodbye to frustrating moments of stripped screw heads and hello to a smooth, efficient installation process.

Ultimately, choosing black oxide sheet metal screws is about more than just aesthetics; it’s about quality, durability, and a professional finish. They offer a superior combination of visual appeal and practical benefits that make them a worthwhile investment for any project. From improving the look of your home decor to ensuring the longevity of your outdoor structures, our best black oxide sheet metal screws will deliver exceptional performance and lasting value.

Black Oxide Sheet Metal Screw Applications

Ever wondered where you might actually use these black oxide sheet metal screws besides, well, screwing sheet metal together? They’re surprisingly versatile. Think about electronics enclosures – those metal boxes that house all the sensitive circuits for your home entertainment system or your computer. Black oxide screws help hold those together securely while also preventing unwanted reflections inside the enclosure, crucial for optimal performance.

Another common application is in automotive interiors. Those panels covering the doors, dashboards, and even the trunk? Yep, black oxide screws are often hiding underneath, keeping everything firmly in place without drawing attention to themselves. Their corrosion resistance is also important here, especially in vehicles exposed to varying temperatures and humidity.

Consider appliance manufacturing too. The outer casings of your washing machine, dryer, or refrigerator are often assembled using sheet metal and, you guessed it, black oxide screws. They provide a clean, finished look and blend in well with the overall aesthetic of the appliance, while also withstanding the vibrations and stresses of everyday use.

And let’s not forget DIY projects. Whether you’re building a custom computer case, repairing a metal shed, or crafting a unique piece of furniture, black oxide sheet metal screws are a reliable and readily available fastener. Their understated appearance makes them ideal for projects where you want the focus to be on the overall design rather than the hardware itself.

Choosing the Right Size and Type

Selecting the right size and type of black oxide sheet metal screw is just as important as choosing the material itself. Imagine using a screw that’s too short to adequately grip the materials – it’s a recipe for disaster! Conversely, a screw that’s too long might protrude through the back and cause damage or injury. Take the time to measure the combined thickness of the materials you’re joining and select a screw with a shank length that provides ample thread engagement.

Then there’s the head style to consider. Flat head screws are ideal for applications where you want a flush finish, while pan head screws offer a larger bearing surface for increased holding power. Oval head screws provide a slightly decorative look, perfect for projects where aesthetics are a concern. Don’t underestimate the importance of choosing the right head style for your specific application.

And what about thread type? Type A screws are designed for use in thinner sheet metal, while Type AB screws can be used in both sheet metal and heavier materials. Self-drilling screws, also known as TEK screws, have a drill point that eliminates the need for pre-drilling, saving you time and effort. The right thread type will ensure a secure and lasting connection.

Finally, think about the drive type. Phillips head screws are a common and versatile option, but they can be prone to cam-out if too much pressure is applied. Square drive (Robertson) screws offer better torque transfer and are less likely to strip. Torx drive screws provide even greater torque capacity and are ideal for high-stress applications. Consider the tool you’ll be using and the amount of torque required when choosing the drive type.

Black Oxide Coating: Benefits and Limitations

The black oxide coating on these screws isn’t just for looks – it plays a crucial role in their performance and longevity. One of the primary benefits of black oxide is its ability to provide mild corrosion resistance. This is particularly important in environments where the screws are exposed to moisture or humidity, helping to prevent rust and maintain their structural integrity over time. Think of projects exposed to the elements.

However, it’s important to understand that black oxide is not a rust-proof coating. While it offers some protection, it’s not as effective as other coatings like zinc or stainless steel in highly corrosive environments. If your project is going to be exposed to harsh chemicals or saltwater, you might want to consider a different type of fastener. The coating is more for indoor application.

Another advantage of black oxide is its ability to reduce light reflection. This makes it an excellent choice for applications where you want a discreet fastener that doesn’t draw attention to itself. Imagine a stage set where the lighting is critical, or an optical instrument where stray reflections could interfere with the performance. Black oxide screws can help minimize these unwanted effects.

Finally, the black oxide coating can also improve the lubricity of the screw, making it easier to drive and reducing the risk of stripping the threads. This is especially helpful when working with harder materials or when using power tools. The slight lubrication of the coating can improve installation and reduce wear on tools.

Proper Installation Techniques

Even the best black oxide sheet metal screws won’t perform as expected if they’re not installed correctly. One of the most common mistakes is over-tightening, which can strip the threads or even break the screw. Always use the appropriate amount of torque and avoid forcing the screw. A good rule of thumb is to tighten the screw until it’s snug, then give it a quarter turn more.

Pre-drilling is often necessary, especially when working with thicker materials or when using self-tapping screws. This creates a pilot hole that guides the screw and prevents the material from cracking or splitting. Use a drill bit that’s slightly smaller than the diameter of the screw threads for optimal results. It makes things a lot easier.

When using power tools, be sure to use the correct driver bit and set the clutch to a low setting to prevent over-tightening. Start slowly and gradually increase the torque until the screw is properly seated. Avoid using excessive pressure, as this can damage the screw head or the surrounding material. Test your torque on scrap material first.

And finally, remember to use the right tool for the job. Trying to drive a screw with the wrong screwdriver can lead to stripped heads and frustration. Invest in a good set of screwdrivers or a power drill with a variety of bits to ensure that you always have the right tool at your disposal. And make sure the screw driver is in good shape to avoid damaging screws.

Your Guide to Choosing the Best Black Oxide Sheet Metal Screws

Hey there! So, you’re on the hunt for the best black oxide sheet metal screws? Fantastic! You’ve come to the right place. Finding the perfect screws for your project can feel a little overwhelming, with all the different sizes, types, and coatings out there. But don’t worry, I’m here to break it down for you in a way that’s easy to understand. Think of me as your friendly guide through the world of fasteners.

We’ll cover everything you need to know to make an informed decision, ensuring you choose the screws that will hold strong and look great. Let’s dive in!

1. Material Matters: Choosing the Right Metal

Alright, first things first: the material of your screws. This is super important because it directly impacts the screw’s strength, durability, and resistance to corrosion. You’ll typically find black oxide sheet metal screws made from steel, often carbon steel or alloy steel. Carbon steel is generally more affordable and suitable for many indoor applications.

However, if you’re working on a project that’s going to be exposed to moisture or the elements, you might want to consider stainless steel. While stainless steel screws are more expensive, they offer superior corrosion resistance. Also, think about the material you’re screwing into. You want to ensure the screw material is compatible to avoid any galvanic corrosion issues down the road. The best black oxide sheet metal screws are often made from hardened steel with the black oxide coating providing additional (though limited) corrosion protection.

2. Size Does Matter: Length, Diameter, and Head Type

Okay, let’s talk about size. Choosing the right size screw is absolutely crucial for a secure and aesthetically pleasing result. You’ll need to consider the length, diameter, and head type. The length should be sufficient to penetrate both pieces of material you’re joining together, providing a solid grip. But be careful not to go too long, or the screw might poke through the other side.

The diameter determines the screw’s holding power. A thicker diameter will generally provide a stronger hold, but it also requires a larger pilot hole (if needed). Then there’s the head type. Common head types include flat, pan, oval, and truss heads. Flat heads sit flush with the surface, pan heads have a slightly rounded top, oval heads offer a decorative look, and truss heads have a wide, low-profile head. Choose the head type that best suits your project’s appearance and functionality. Investing time in this consideration will guide you to the best black oxide sheet metal screws for the application at hand.

3. Thread Design: Understanding Different Types

Now, let’s get a little technical and talk about thread design. The thread is what grips the material and holds everything together. Sheet metal screws typically have sharp threads that are designed to bite into the metal. There are generally two main thread types, Type A and Type B.

Type A threads are coarser and designed for thin sheet metal, while Type B threads are finer and better suited for thicker materials or when tapping into existing holes. Some sheet metal screws are also self-drilling, which means they have a special point that allows them to drill their own pilot hole as they’re being driven in. These are great for speeding up the process and ensuring accurate hole placement. Choosing the correct thread will give you the best chance to obtain the best black oxide sheet metal screws.

4. Black Oxide Coating: Advantages and Limitations

The black oxide coating is what gives these screws their distinctive dark finish. It’s not just for looks, though it definitely adds a nice touch. The black oxide coating provides a degree of corrosion resistance. However, it’s important to understand that it’s not as robust as other coatings like zinc plating or stainless steel.

The black oxide coating is a conversion coating that chemically reacts with the metal substrate to form a protective layer. It offers mild protection against rust and other forms of corrosion, especially in dry indoor environments. The black oxide coating also helps to reduce light reflection, giving the screws a stealthy appearance. If you need superior corrosion resistance, especially for outdoor use, you should consider other screw types or materials. But for most indoor applications, the black oxide coating is perfectly adequate and can even prolong the life of your best black oxide sheet metal screws.

5. Drive Type: Choosing the Right Tool Interface

The drive type refers to the shape of the recess in the screw head that your screwdriver or drill bit fits into. Common drive types for sheet metal screws include slotted, Phillips, and Torx. Slotted screws are the most basic, but they can be prone to slipping. Phillips head screws are more common and offer better grip, but they can still cam out (where the screwdriver slips out of the recess under pressure).

Torx drive screws are a popular choice because they provide excellent grip and resist cam-out. They have a star-shaped recess that distributes the torque evenly, allowing you to apply more force without stripping the screw head. Which screw type you choose is mostly personal preference, but is worth noting when deciding on the best black oxide sheet metal screws. Consider the tools you have available and the amount of torque you’ll need to apply.

6. Brand Reputation and Reviews: Learning from Others

In today’s world, it’s easier than ever to research products before you buy. Don’t underestimate the power of brand reputation and customer reviews. Before you commit to a particular brand of black oxide sheet metal screws, take some time to read what other people have to say about them. Look for reviews that mention the screw’s strength, durability, and ease of use.

Pay attention to any recurring complaints, such as screws stripping easily or the black oxide coating wearing off prematurely. A reputable brand is more likely to use high-quality materials and manufacturing processes, resulting in screws that perform as expected and last longer. Also, reputable brands often have better customer support if you encounter any issues with your purchase. So, do your homework and choose a brand that has a solid track record. Finding what customers deem the best black oxide sheet metal screws based on use-case and feedback can be valuable information for your decision.

7. Cost vs. Quality: Balancing Your Budget

Finally, let’s talk about cost versus quality. It’s tempting to go for the cheapest option, especially if you’re buying a large quantity of screws. However, it’s important to remember that you often get what you pay for. Cheap screws may be made from inferior materials, which can lead to them breaking, stripping, or corroding quickly.

Investing in higher-quality screws may cost a bit more upfront, but it can save you money in the long run by preventing the need for replacements or repairs. Consider the overall cost of your project and the consequences of using low-quality screws. If the screws are critical to the structural integrity of your project, it’s worth spending a little extra to ensure they’re up to the task. Look for a balance between cost and quality that fits your budget and needs. The goal should be obtaining the best black oxide sheet metal screws that are also affordable.

FAQ

What exactly *is* black oxide and why is it used on sheet metal screws?

Black oxide is essentially a chemical conversion coating formed on the surface of the metal. Think of it as a controlled rusting process that creates a thin, protective layer. It’s not like paint or plating, which just sit on top; black oxide actually becomes part of the metal surface!

The cool thing about black oxide on sheet metal screws is that it offers some corrosion resistance and it also reduces light reflection, making the screws less noticeable. Plus, it can improve lubricity, making it easier to drive the screws in. It’s a popular choice for a stealthy, durable finish that won’t flake or peel.

Are black oxide sheet metal screws *really* rust-resistant? I live in a humid area!

Well, that’s a great question! While black oxide offers some rust resistance, it’s important to understand it’s not a magic bullet, especially in highly humid or corrosive environments. Black oxide by itself provides mild protection and requires an oil treatment to enhance corrosion resistance.

If you live in a super humid area or near saltwater, you might want to consider using stainless steel sheet metal screws instead. They’re designed for tougher conditions and offer much better protection against rust. However, for most indoor applications or moderately humid areas, black oxide screws should hold up just fine!

How do I choose the right size and type of black oxide sheet metal screw for my project?

Choosing the right screw can feel a bit overwhelming, but it’s not too bad! First, you’ll want to think about the thickness of the sheet metal you’re working with. The screw needs to be long enough to go through both pieces and grab securely. Also, consider the hole size – you don’t want the screw to be too tight or too loose.

As for the type, there are different head styles (like pan, flat, or oval) and point types (like self-tapping or drill point). Self-tapping screws are great for thinner materials because they create their own threads as you screw them in, while drill point screws can drill their own pilot holes. Read the screw’s description carefully to see what material it is suited for.

What’s the difference between a “self-tapping” and a “self-drilling” black oxide sheet metal screw?

Alright, let’s clear up the self-tapping vs. self-drilling confusion! A self-tapping screw has a sharp point and is designed to create its own threads as you drive it into the sheet metal. However, you usually still need to pre-drill a pilot hole for it to work effectively, especially in thicker materials.

On the other hand, a self-drilling screw (also called a Tek screw) has a drill-bit-like tip that can actually drill through the sheet metal before the threads engage. This eliminates the need for a separate pilot hole in many cases. So, if you’re working with relatively thin sheet metal, a self-drilling screw can save you a lot of time and effort.

Can I reuse black oxide sheet metal screws, or should I always use new ones?

Reusing screws is a common question! Generally, it’s best to use new screws whenever possible, especially for critical applications. Each time you drive a screw, the threads can get slightly worn or damaged, which can reduce their holding power.

However, if you’re working on a less critical project and the screws are still in good condition (no stripped threads or damaged heads), you might be able to reuse them. Just be sure to inspect them carefully and avoid over-tightening when you re-install them. It’s always better to be safe than sorry!

How can I prevent the black oxide coating from scratching or chipping during installation?

That’s a valid concern! To minimize scratching or chipping, start by using the right size screwdriver or drill bit. Using the wrong size can cause the tool to slip and damage the coating. Also, avoid applying excessive pressure while driving the screws. Let the screw do the work, and go slowly.

Another good tip is to use a screwdriver or drill bit with a magnetic tip. This will help hold the screw in place and prevent it from wobbling around, which can also lead to scratches. With a little care and the right tools, you can keep your black oxide screws looking great!

Where’s the best place to buy black oxide sheet metal screws?

That’s a great question! You’ve got several good options. Big box hardware stores like Home Depot or Lowe’s are always a reliable choice, especially if you need the screws right away. They usually have a good selection of sizes and types in stock.

You can also check out online retailers like Amazon or specialty fastener websites. Online stores often offer a wider variety of screws and can be more convenient if you’re buying in bulk. Plus, you can read reviews from other customers to get a better sense of the quality of the screws. Just be sure to compare prices and shipping costs before you buy!

Conclusion

So, there you have it! We’ve explored the world of the best black oxide sheet metal screws, highlighting top contenders and essential factors to consider. Armed with this knowledge, you’re now well-equipped to select the perfect fasteners for your next project. Remember, choosing the right screws can make all the difference between a flimsy outcome and a durable, professional-looking creation.

Don’t hesitate to put your newfound understanding to the test. Get those projects started, knowing you’ve made an informed decision. Whether it’s crafting a unique piece of furniture or tackling a vital repair, trust that with the right resources and, of course, the best black oxide sheet metal screws, you’ve got what it takes to bring your vision to life! Now go out there and build something amazing!